IGCT integrated Gate Commutated Thyristors,which is the integration of the GTO chip with the anti-parallel diode and gate driver circuit, and

then the gate driver is connected in a low inductance mode at the periphery. This is the GTO (Gate Turn Off).

IGCT is in the same vein as SCR in the rectification process, SCR is the abbreviation of Silicon Controlled Rectifier. Thyristors have one-way, two-way,

turn-off and light control several types. It has the advantages of small size, light weight, high efficiency, long life, easy control, etc., and is widely used

in various automatic control and high-power electric energy conversion occasions such as controlled rectification, voltage regulation, inverter and

contactless switch.

Unidirectional thyristor is a controlled rectifier electronic component that can be turned off by an external control signal, but once it is turned on, the external signal cannot be turned off, and it can only be turned off by removing the load or reducing the voltage at both ends. Unidirectional thyristor is a four-layer, three-terminal semiconductor device composed of three PN junction PNPN. Compared with the diode with one PN junction, unidirectional thyristor is controlled by the control electrode current. Compared with a triode with two PN junctions, the difference is that the thyristor has no amplification effect on the control electrode current. Bidirectional thyristor has the characteristics of turning on and off in two directions. Bidirectional thyristor is essentially two anti-parallel unidirectional thyristor, which is a semiconductor device composed of four PN structures formed by NPNPN five layers of semiconductors and has three electrodes. Because the structure of the main electrode is symmetrical (all from the N layer), its electrodes are not called anode and cathode like unidirectional thyristors, but the first electrode A1 that is very close to the control is called the second electrode A2. The main disadvantage of bidirectional thyristors is the low ability to withstand the voltage rise rate. This is because when the bidirectional thyristor is switched on in one direction, the carriers in each layer of the silicon wafer have not returned to the position of the cutoff state, and corresponding protection measures must be taken. Bidirectional thyristor components are mainly used in AC control circuits, such as temperature control, light control, explosion-proof AC switches and DC motor speed regulation and commutation circuits. The thyristor is always in the open state above the maintenance current, the turn-off current is high, the control is difficult, and the turn-off speed is slow. In the inverter link, SCR has excellent performance in LCI (load commutated inverter), which can achieve large power, high voltage and large current. Diode (uncontrolled rectifier device) and SCR (semi-controllable) rectifier do not require PMW to meet the two-quadrant inverter work, PWM requires IGBT (full control) and other devices.

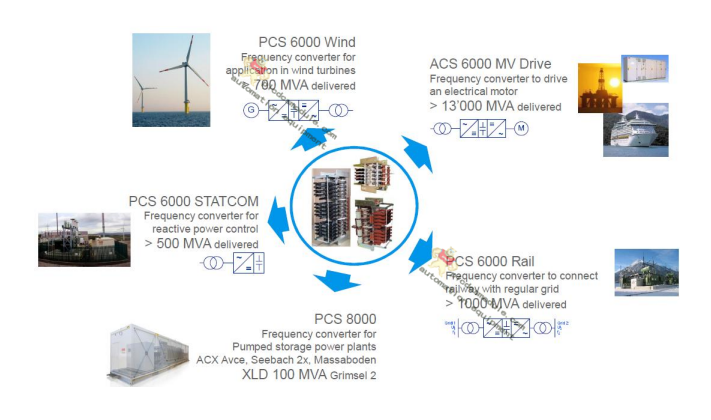

IGCT integrated Gate Commutated Thyristors (IGCT integrated gate commutated thyristors = gate commutated thyristors + gate units) is a new type of power semiconductor switching device developed by medium voltage inverter for use in large power electronics packages. It was proposed by ABB in 1997. IGCT has made great progress in power, reliability, switching speed, efficiency, cost, weight and volume, and has brought a new leap to power electronic complete sets. IGCT integrates the GTO chip with the anti-parallel diode and gate drive circuit, and then connects it with the gate driver in a low inductance mode at the periphery, combining the stable turn-off ability of the transistor and the advantages of the low on-state loss of the thyristor, and gives play to the performance of the thyristor in the on-stage, and presents the characteristics of the transistor in the off-stage. IGCT has the characteristics of large current, high blocking voltage, high switching frequency, high reliability, compact structure, low on-off loss and so on, and has a good application prospect. IGCT has been used in power system grid devices (100MVA) and medium power industrial drive devices (5MW) IGCT has been successfully applied in the field of medium voltage inverter for 11 years (until 2009), because the high-speed switching capability of IGCT does not need buffer circuits, so the number of power components required is less, and the reliability of operation is greatly increased.

The Insulated Gate Bipolar Transistor (IGBT) is a compound fully controlled voltage-driven power electronic device composed of BJT(bipolar triode) and MOS(insulated gate field effect tube), which combines the advantages of the high input impedance of MOSFET and the low on-voltage drop of GTR. The driving power is small and the saturation pressure is reduced. The diode is added between the collector and the emitter, mainly for continuous flow, and due to the inductive load, the IGBT turn-off moment will produce a very high self-inductive reverse voltage at both ends of the IGBT, which may breakdown the IGBT. The parallel diode shorted out this "self-inducted inverting voltage", protecting the IGBT.

IGBT

The IGCT combines the high-speed switching characteristics of the IGBT (insulated gate bipolar transistor) with the high blocking voltage and

low on-loss characteristics of the GTO (gate off thyristor), and the trigger signal is generally transmitted to the IGCT unit through the optical fiber.

In the phase module of the ACS6000 marginal rectifier unit, each phase module consists of an IGCT and a continuing diode, a clamp capacitor, and

a damping resistor, and is provided with energy by an independent gate power supply unit GUSP.

IGBT module is only a part of the power device package as a module, IGBT module products can generally be single tube, double

tube (half bridge) or 6 tube (full bridge), there are also three levels of 12 just package as a module. Because it has been packaged as

a module, it is electrically insulated and the installation process is simple; IGCT does not have this advantage, which makes the design, installation

and maintenance of the system complicated, and the contradiction between insulation and heat dissipation makes the system more problematic.

IGBT low power drive can be done together, high power requires a separate drive board. dsp is the control core, as well as external io, internal

signal acquisition, processing, drive signal buffering, drive signal isolation, amplification, in order to reach the GE pole of IGBT. Optical fiber isolated

transmission drive signal.

The IGBT on-off frequency is high, but dv/dt is the on-off speed is low, there is a certain contradiction, only the speed is fast enough, the frequency

can be high enough. Plus the absorption circuit or IGBT to take soft off, the absorption circuit is the possible 10kv/us absorption, soft off refers to reduce

the switch off speed, artificially caused off the tail, the benefit is to reduce dv/dt, the harm is to increase the IGBT loss, so to carefully adjust the off time.

When the IGBT driver circuit turns off the IGBT, a negative voltage is applied at GE (positive voltage is applied on), and a micro resistor is placed at the

micro capacitor, so that the GE voltage drops slowly, thereby reducing dv/dt.

Common IGBT parameters: 6500V/ Max 750A; 4500V/ 1200A; 3300V/ 1500A; 1700V/3600A; 1200V/ 3600A. 700V and 2500V are rarely used.

There are many below 600V, which we won't discuss here. Above 380V, IGBT voltage should be above 1200V. Although there are 6600 and 6000V

motors, 6500V IGBT is not suitable for 6500V, the price is high, a 20,000 or so, and the two-level output voltage of 3300V, the maximum is only 750A pipe,

the output dv/dt is too large, the three-level output voltage of 4160V, 4160 in domestic applications are few. The use of a five-level 4500V tube can output

6600V, so the 6500 tube is not used.

1, IGCT has the characteristics of large current, high blocking voltage, high switching frequency, high reliability, compact structure, low on-off loss, etc.,

and causes low cost, high yield, and has a good application prospect.

2, compared with IGBT, IGCT was put on the market later, the application is not as wide as IGBT, and the technology maturity is not as good as IGBT.

The current IGBT and IGCT open and close losses are similar, and the efficiency of the inverter is not different. The main advantage is that the voltage

withstand of IGCT is currently higher than that of IGBT, and the device is reduced when applied to high voltage inverters. However, the current wind power

converters are 690V, and the voltage withstand of IGBT is enough. IGBT and IGCT, which is the development direction of power electronic devices? At present,

the academic community is arguing that although IGCT appeared late, at least for now, it is not clear what advantages it has over IGBT. However, it is also

possible that with the development of technology, the two will go hand in hand, or both will be replaced by some new device.

The counterpart to IGCT is IEGT, also known as press-mounted IGBT (PPI).

3005319639

3005319639